منزل / جميع / Microchannel heat exchanger / micro-channel heat exchanger / Micro System /

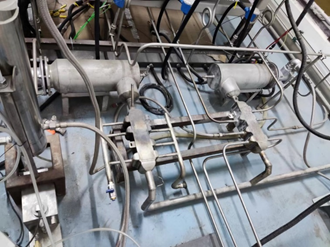

HZSS High-Efficiency Steam Hydrogen Reformer Production OEM Applications

HZSS High-Efficiency Steam Hydrogen Reformer Production OEM Applications

The hydrogen reformer converts methanol, water, and other fuels through reforming heat exchange to produce hydrogen gas.

| فئات | Micro System |

|---|---|

| علامة تجارية | SHENSHI Heat Exchanger Manufacturer |

| Material | 316L |

| Brand | HZSS |

| Customized | Support |

| ميناء | Shanghai/Ningbo/Guangzhou |

| طريقة الدفع | L/C, T/T |

| وقت تحديث | 2025/6/23 |

معلومات مفصلة

Steam Hydrogen Reformer

The hydrogen reformer converts methanol, water, and other fuels through reforming heat exchange to produce hydrogen gas.

Features

1. High compactness: small size, light weight and space saving.

2. Wide range of applicable media: working media can be air, water, hydrogen, etc.

3. High efficiency: extremely high heat transfer coefficient to achieve the highest heat exchange efficiency.

4. Material diversification: stainless steel, superalloy, etc.

5. High temperature resistance: up to 1000 ℃.

6. Diversified structure: there are PCHE and PFHE structure options.

Working principle

The hydrogen reformer converts methanol, water, and other fuels through reforming heat exchange to produce hydrogen gas.

Related industries

SOFC

Surplus electricity is used to produce hydrogen, and hydrogen is used as the energy carrier for energy storage to reduce energy waste.

Waste heat recovery

Shenshi technology's heat exchanger can also provide convenience for waste heat recovery systems, and the circulating waste heat can be used as a heat source for pre heat exchange.

Title

Sample Content

Title

Sample Content

الرجاء ارسال رسالة إلينا

هل تبحث عن حل موثوق لإدارة الطاقة الحرارية منخفض الكربون؟ نوفر لعملائنا بسرعة نصائح حول المنتجات والدعم الفني وخدمات مخصصة. لمزيد من المعلومات، تواصل معنا.

- اسم

- هاتف

- *لقب

- *محتوى