Tubular reactor

Efficient mixing and heat transfer are achieved by rotating flow in a spiral tube.

| فئات | Microreactor |

|---|---|

| علامة تجارية | SHENSHI Heat Exchanger Manufacturer |

| Application | Medicine, pesticide, gunpowder, dye, environmental |

| Material | Stainless steel, Hastelloy, titanium, tantalum, ni |

| ميناء | Shanghai/Ningbo/Guangzhou |

| طريقة الدفع | L/C, T/T |

| وقت تحديث | 2025/6/23 |

معلومات مفصلة

Product Introduction

A reactor that uses heat transfer between a fluid in a pipe and a heating or cooling medium to carry out chemical reactions.

Features

1. high reaction rate: can provide a large specific surface area, promote the contact between the reactants, improve the reaction rate.

2. flexible process flow: suitable for continuous flow reaction, process flow is easy to control and optimize.

3. high selectivity: the improvement of the flow state in the tubular reactor helps to improve the selectivity of the reaction.

4. accurate flow rate control: by adjusting the feed speed, to achieve accurate flow rate control, affect the reaction results.

5. modular design: modular design can be achieved, easy to produce and expand.

6. high safety: with good tightness, to ensure the safety and reliability of the reaction process.

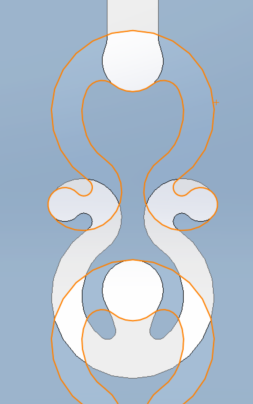

Working principle

Using the principle of spiral flow, the raw material forms a continuous spiral flow in the tube to promote the reaction. In the reaction process, the raw material is continuously fed into the spiral tube through the pump or other conveying equipment, and the spiral flow is formed in the tube. This flow mode can make the raw material fully contact with the catalyst or reactant in the tube, increase the effective concentration and contact time of the reactant, and improve the reaction rate and product yield.

Related industries

Medicine

Optimize drug synthesis with efficient heat and mass transfer characteristics. Help new drug research and development, rapid screening conditions. Achieve continuous production, improve efficiency and reduce costs.

Petrochemical Industry

Efficient heat and mass transfer to optimize critical processes such as heavy oil cracking. It helps the research and development of new processes, and promotes the continuity, efficiency and low-cost of petrochemical production.

Pesticide

Strengthen the synthesis efficiency and product quality, accelerate the research and development of new pesticides, promote the continuity and automation of pesticide production, and reduce costs.

Dye

Optimize the dye synthesis process, strengthen the color mixing uniformity, and help the development of new dyes; Improve the continuity and efficiency of dye production.

Essence And Fragrance

Efficient synthesis of complex aroma ingredients, precise allocation of aroma ratio, accelerate new product development; Efficient automation of production processes.

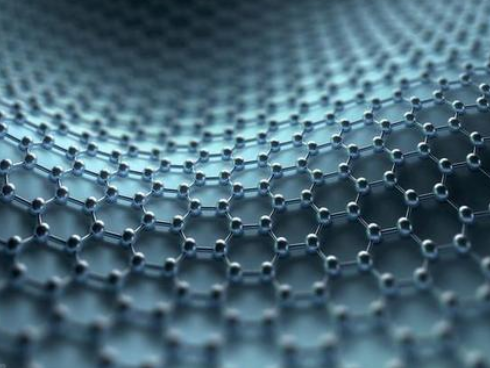

Advanced Material

Promote the synthesis of nanomaterials, strengthen the uniform mixing of material components, and help the rapid development of new materials.

الرجاء ارسال رسالة إلينا

هل تبحث عن حل موثوق لإدارة الطاقة الحرارية منخفض الكربون؟ نوفر لعملائنا بسرعة نصائح حول المنتجات والدعم الفني وخدمات مخصصة. لمزيد من المعلومات، تواصل معنا.

- اسم

- هاتف

- *لقب

- *محتوى